Frequently asked questions

What is a WMS?

A Warehouse Management System (WMS) is a software solution that provides visibility into all of a company’s inventory and manages supply chain operations.

The WMS system can be independent or integrated with the ERP system, in this case a complete solution that covers all activities from taking customer orders and issuing invoices, to loading products for delivery.

The WMS solution offers the possibility to increase the level of use of labor, space and equipment investments, through better coordination and optimization of the use of resources of any kind. In particular, WMS systems are designed to meet the requirements of an entire supply chain, globally, for distribution, retail, production and service companies.

What are the benefits of the WMS solution?

- Helps optimize stocks

- Increases the accuracy of the picking process

- Facilitates the inventory process

- Track batch traceability

- Significantly reduces the time spent handling goods

- Provide real-time stock information

- Contributes to increasing the productivity of warehouse operators

- Shortens the integration time of new operators

- Provides increased visibility into all warehouse activities

Why WMS in the cloud?

Thanks to the Internet and digital technology, customer purchasing patterns have changed and added complexity to the supply chain. FluxVision WMS in the cloud provides real-time visibility, scalability and sensitivity to market reactions.

The process of honoring omnichannel orders

To stay competitive, you need to adapt quickly. FluxVision WMS in the cloud supports complex, omnichannel order fulfillment processes.

You do not pay extra for upgrades

With FluxVision WMS you always have the latest version of the software, without having to pay extra. The cost of the annual subscription includes automatic access to scheduled regular updates at no extra cost. Upon request, there is the possibility of developing additional features for a fee.

Reduce TCO

Cloud solutions offer an almost immediate return on investment and a low total cost of investment. The solution comes ready to integrate with multiple systems and solutions, to fully connect all your logistics processes.

There are no costs for IT infrastructure or costs for hardware, system or database administrators. What was once a substantial expense now becomes a predictable and much lower operating cost, allowing you to keep your profit margins.

Meet market demands faster

FluxVision WMS in the cloud gives you the scalability you need to quickly expand your supply chain operations and meet changing market conditions. If needed, you can easily add new users to cover peak periods or other changes. When new opportunities arise, you will be prepared.

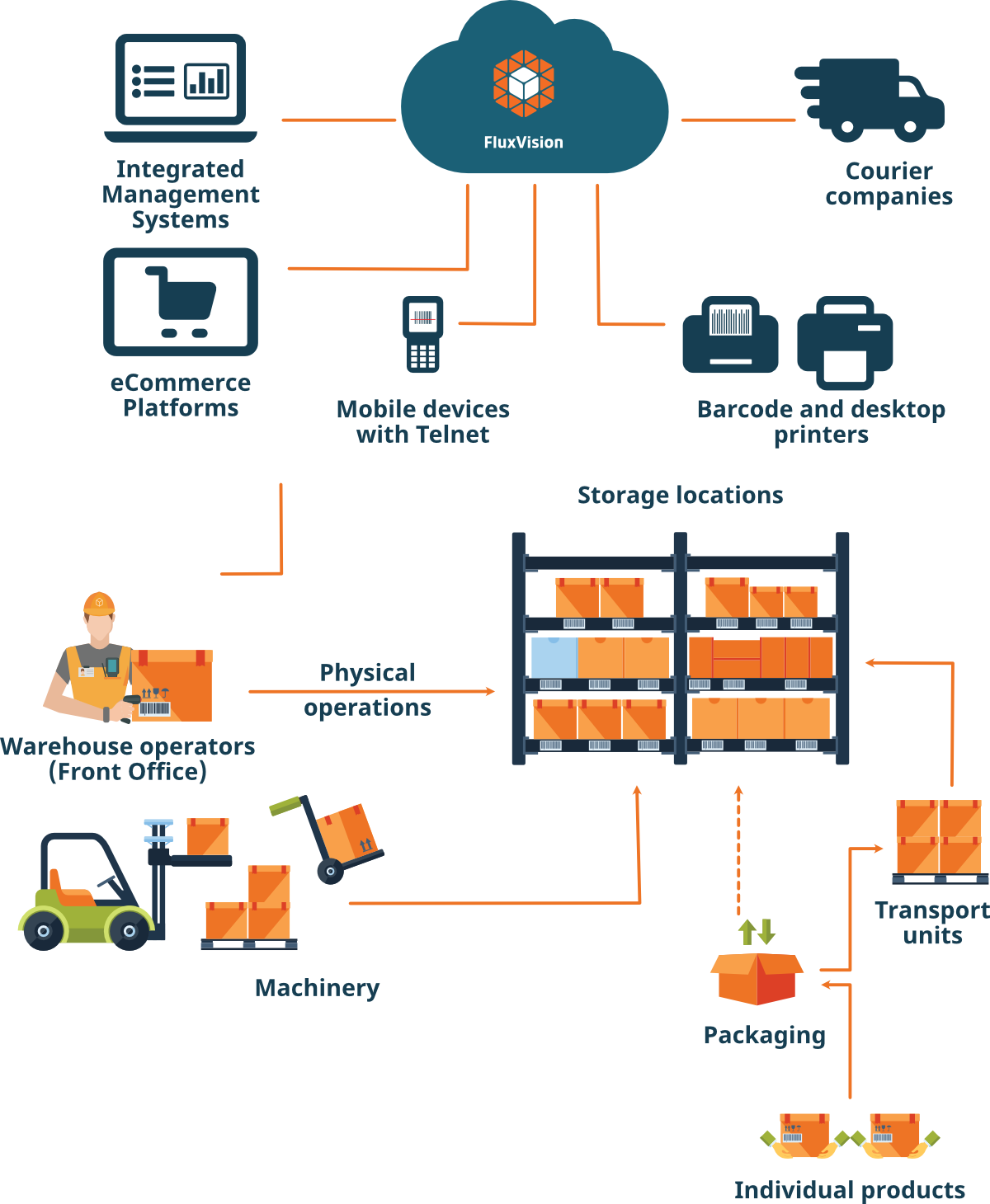

Seamless integration – WMS and ERP

FluxVision WMS is natively integrated with SocrateERP, being developed on the SocrateCloud platform. Being an open platform, it also allows the integration of the warehouse management system with any other computer systems and devices you need in the warehouse.

What activities does a WMS cover?

Receiving goods is done with the help of mobile barcode readers. The goods are scanned when they arrive in the warehouse. Purchase orders are created in the ERP system and then forwarded to the WMS. Upon receipt, the differences between them and the results of the goods scan are recorded and sent back to the ERP to update the orders.

Putaway. With the help of WMS, warehouse operators have a clear picture of the space available for storage. The goods can be placed on the basis of the suggestions provided by the WMS, so that access to it can be made as quickly as possible and the space available for storage can be used to the maximum.

Picking is the activity of collecting goods from the warehouse and is performed based on customer orders registered in ERP. Operators view the commands directly on the mobile device and perform the picking according to the optimal route suggested by WMS. Modern technologies now allow picking to be performed by various methods, such as light pick-up or voice-pick.

Packaging and labeling. After picking, customer orders are packaged for delivery to the destination based on WMS-generated delivery lists. With a printer, the label can be generated and attached to each order so that it can be identified more easily.

Delivery. Orders are loaded into cars according to pre-set rules, depending on where they are to be delivered.

Inventory. The entire inventory process is done using FluxVision WMS based on the inventory lists generated by it. The use of barcode scanners helps to increase the accuracy and completeness of the inventory process in a much shorter time.